Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

1. What is fluorinated graphite

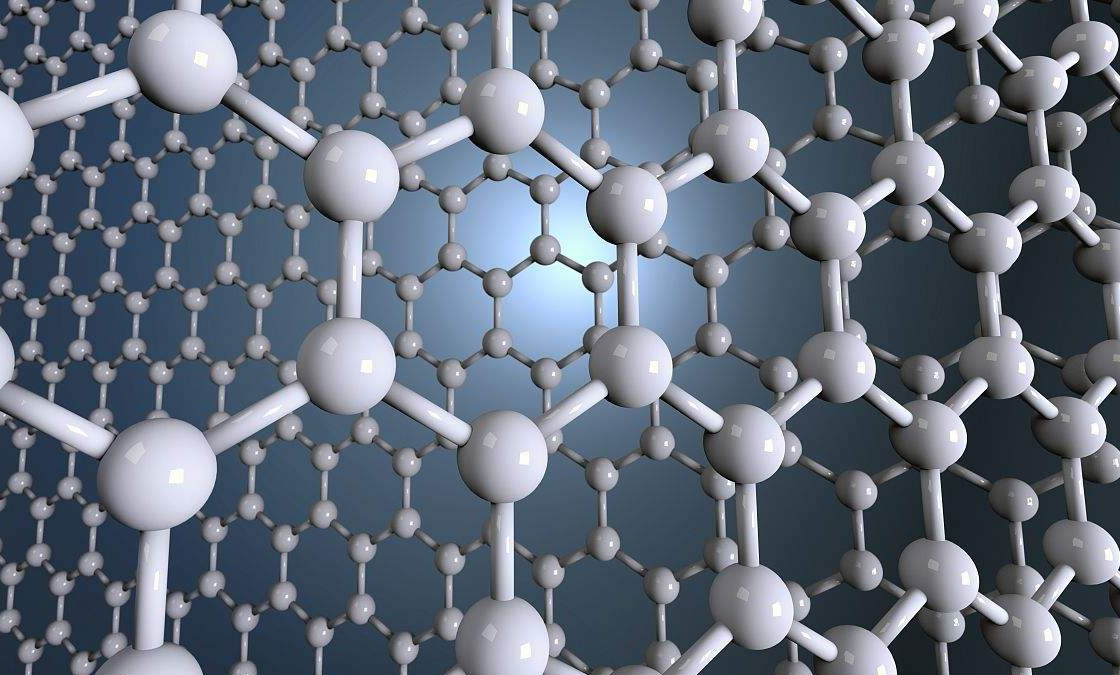

Graphite fluoride is a type of interlayer compound produced by the direct reaction between graphite carbon and fluorine, and its chemical structure can be (CFx)n. Indicates that the F/C ratio (x) is an indefinite value, and the change interval is 0

Highly fluorinated graphite has excellent thermal stability, is an electrical and thermal insulator, is not corroded by strong acids and alkalis, and its lubricating performance exceeds MoS2 and flake graphite.

Because fluorinated graphite has many excellent properties, it has a wide range of applications in the fields of military, aviation, aerospace, metallurgy, electromechanical, chemical and special materials, and is currently the most economically promising new graphite product.

2. Synthetic method of fluorinated graphite

(1) Direct synthesis method

Solid carbon and gaseous fluorine are heated and reacted within a certain range. The raw materials of this process only involve solid carbon and gaseous fluorine. The external conditions are only the temperature reaction effect, which is only related to the reactants themselves and the reaction conditions. The earliest synthetic method is also the most mature industrial production method.

(2) Catalytic synthesis method

In the reaction system of graphite and fluorine gas, if there is a small amount of metal fluoride, fluorination can also be realized under lower than normal conditions. The metal fluoride plays a catalytic role in the fluorinated graphite prepared here. Containing a small amount of metal fluoride, although the amount is small, it changes the properties of fluorinated graphite, especially the conductivity increased by an order of magnitude.

(3) Solid-solid synthesis method

This method uses solid fluoropolymer and graphite to mix and heat to 260°C in an inert gas to prepare fluorinated graphite. This synthesis method has improved safety, but the degree of fluorination is low and the product is uneven.

(4) Electrolysis method

Electrolysis of carbon or graphite materials in anhydrous hydrofluoric acid can produce new fluorinated graphite, that is, circulating hydrofluoric acid between the anode and cathode, so that fluorinated graphite can be synthesized continuously. This method is controlled by The concentration of the reaction solution, the electrolysis temperature and the amount of conductive agent added are achieved, but the degree of fluorination is low, and the product F/C is not uniform. The process of this method is still being further improved.

3. Uses of fluorinated graphite

(1) Solid high-efficiency lubricant

Highly fluorinated graphite has higher lubricity than virgin graphite, molybdenum disulfide (MoS2), etc. The structure of this highly fluorinated graphite is staggered, and the surface carbon atoms 2p electrons participate in the formation of Sp3 hybridization and fluorine atoms. Covalent bond, so that fluorinated graphite loses part of its conductivity. The upper and lower surfaces of the layers are densely bound with fluorine atoms. Due to the electronegativity of the fluorine atoms, there is a repulsive force between the fluorine atoms on the adjacent layers, so that the interlayer spacing of the carbon layer extends from 3.35Å of graphite to 7.08Å, and the interlayer energy is changed from The 39.681 kJ/mol of graphite is reduced to 8.365 kJ/mol, so the layer is easy to slide and has stronger lubricity.

Experiments show that under the conditions of high temperature, high pressure and high load (882kg/cm2), high fluorinated graphite still maintains good lubricating properties, so it is called the "king of lubrication".

Fluorine gas is prepared by electrolysis of molten salt KF•2HF, and then the fluorine gas and graphite are reacted at 500°C to prepare fluorinated graphite materials, and the friction coefficients of fluorinated graphite, graphite and molybdenum disulfide are tested. It was found that the friction coefficient of fluorinated graphite is smaller than that of graphite and MoS2, which proves that fluorinated graphite does have excellent lubricating properties.

(2) Electrode materials for lithium carbon fluoride batteries with high energy density

Graphite fluoride has good chemical and thermal stability, extremely low surface energy, and extremely high electrical activity. Graphite fluoride is suitable as anode material for high-energy batteries. CF0.5-0.99 Graphite fluoride is most suitable as anode material for high-energy batteries with fluorine content. High is beneficial to reduce the anode volume and miniaturize the battery.

In recent years, electrode materials for lithium fluorinated carbon batteries have become the largest application field of fluorinated graphite.

Although highly fluorinated graphite CF1.1-1.26 contains high fluorine content, it is necessary to add ion conductive agent Li due to excessive resistivity. Low-fluorinated graphite is used as the electrode material of the lithium battery, and the lithium fluoride electrode is synthesized in situ. Studies have shown that the reaction has a wide applicable temperature range, high and stable discharge electromotive force, high energy density, safety and environmental protection, slow self-discharge, and a service life of more than 10 years.

The functionalized fluorinated graphite was prepared using the mixed gas of fluorine and helium at different temperatures, and the fluorinated graphite with fluorine-to-carbon ratios of 0.89, 0.66 and 0.47 were prepared. The results show that the fluorinated graphite with the best performance has a fluorine-to-carbon ratio of 0.47, and its discharge voltage can reach up to 2.8V. The prepared fluorinated graphite with a fluorine-to-carbon ratio of 0.89 has a specific capacity of 721mA/g.

(3) Hydrophobic and oil-proof material

Due to the introduction of fluorine atoms, the surface Gibbs free energy of fluorinated graphite is significantly reduced, and the interlayer energy is very small, and it is not wetted by water at all. Graphite fluoride is one of the most hydrophobic materials due to its strong covalentness and low polarization of C-F bond.

For example, the contact angle of water on paraffin wax is 90°-100°. Even the most difficult-to-lubricate PTFE, its contact angle is only about 110°, while the contact angle of water to graphite fluoride is as high as about 145° , So fluorinated graphite can be used as a high-performance water repellent or hydrophobic material.

(4) Fluorinated graphite fiber heat dissipation material

The fluorinated graphite fiber made by the reaction of fluorine gas and graphite fiber can be used to make the heat dissipation material of electronic tester.

(5) Sound-absorbing materials

Graphite fluoride can be coated on the surface of organic matter to make sound-absorbing materials, which can be used in internal combustion engines and other exhaust emissions to reduce noise pollution.

(6) Release agent and abrasive

The low surface energy of graphite fluoride enables it to be used as a mold release agent for molding, plywood molding, powder molding, sintering and fine pressing, and plastic metal molds, and as an abrasive for the grinding of optical devices.

(7) Positive electrode additives for alkaline zinc-manganese batteries

Graphite fluoride can also be used as a positive electrode additive for alkaline zinc-manganese batteries. Graphite fluoride can significantly increase the discharge capacity of the battery. The best additive content is 5%. Graphite fluoride with different degrees of fluorination can increase the discharge capacity of the battery. It is also different. The best effect is when the fluorine content is 35%.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.